8 Stage Of Process Involved In Caste Iron And The Reason Why People Concluded The Iron Pans Are Good For Cooking

Birth Of Cast Iron:

When we are eager to use a product we should know the origin and the way of making. Its our pleasure to explain about the cast iron.

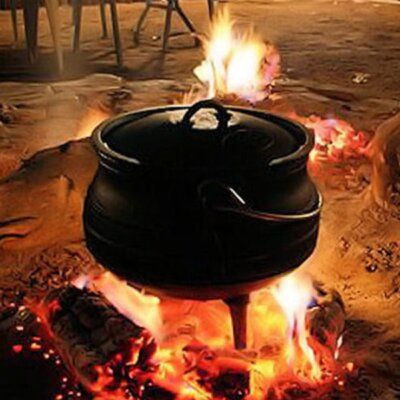

There is a long history of cooking with cast-iron vessels. We the Asians are the inventors of these cookware but The first mention of a cast-iron kettle in English appeared in 679 or 680, though this wasn't the first use of metal vessels for cooking. In 1180 the term pot came into use. At the time they came to know It has the capacity to observe the direct heat.

How they concluded that the cast iron is best for cooking?

The Strong and sustainability gave them the confident to cook also the cooked food are so delicious and it was evenly cooked. So they are very comfortable in cooking with the iron pots but the are struggled with the rust formation and found that the oil coating will help to reduce it. After that The Han Dynasty in China was invented the cast iron cook wares will create the great impact in Kitchen so it was staple in households all over the world.

Do you know how the cast iron production and process will be ?

The production of cast iron pots and pans follows a specific process that involves casting and finishing techniques. Here's an overview:

- Pattern Making: The production process typically begins with the creation of patterns, which are exact replicas of the desired pots and pans. These patterns are often made from wood, metal, or plastic and are used to create the molds for casting.

- Mold Making: Sand molds are commonly used in the production of cast iron cookware. The patterns are pressed into specially prepared sand to create cavities in the shape of the pots and pans. The molds are then assembled and prepared for casting.

- Melting and Pouring: Cast iron is melted in a furnace, typically using a combination of pig iron, scrap metal, and alloying elements to achieve the desired properties. Once molten, the iron is poured into the prepared molds. The molten iron fills the cavities and takes the shape of the pots and pans.

- Cooling and Solidification: After pouring, the molten iron cools and solidifies within the molds. This process may take several minutes to hours, depending on the size and thickness of the cookware.

- Shakeout: Once the cast iron has cooled and solidified, the molds are removed, and the newly cast pots and pans are shaken out. Any excess sand or debris is removed from the surface of the cookware.

- Finishing: The cast iron cookware undergoes various finishing processes to remove any rough edges, excess material, and surface imperfections. This may involve grinding, machining, or sandblasting to achieve the desired surface finish and dimensional accuracy.

- Seasoning: Cast iron cookware is often seasoned to create a natural non-stick surface and prevent rusting. Seasoning involves coating the cookware with a thin layer of oil and heating it to a high temperature, which polymerizes the oil and forms a protective layer on the surface of the cookware.

- Quality Control: Throughout the production process, quality control measures are implemented to ensure that the cast iron pots and pans meet the required standards for strength, durability, and appearance.

Ancient Un Seasoned Cast Iron Kadai VS Pre Seasoned Cast Iron Kadai for easy cooking

Once the production process is completed, the cast iron cookware is ready for packaging and distribution to retailers or consumers. Cast iron pots and pans are prized for their excellent heat retention, durability, and versatility in the kitchen. They are used for a wide range of cooking techniques, including frying, searing, baking, and roasting.

Agro Shoppy has quite the selection! Since it was available in reasonable price compare to Market price Agroshoppy is the destination for cast iron kitchen essentials.

Help

Help